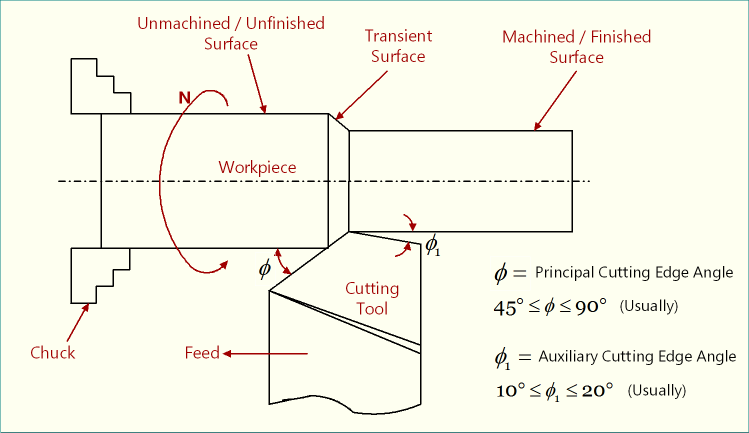

Geometry, orientation and material of a cutting tool are the three important factors that determine economy and performance of machining (machinability). Geometry of cutting tool consists of rake angles, clearance angles, auxiliary clearance angles, cutting angles and nose radius. All these angles basically express orientation of various tool point surfaces of a turning tool. The three important surfaces of a single point turning tool (SPTT) are:

- Rake surface—chip flowing surface.

- Principal flank surface—remains in contact (for small length) with the machined / finished surface.

- Auxiliary flank surface—in some specific operations, it also remains in contact with the machined / finished surface.

What is Principal Cutting Edge in an SPTT?

The line of intersection between rake surface and principal flank surface is known as Principal Cutting Edge. The inclination of this edge can be expressed by various cutting edge angles. There are various ways for designating SPTT, such as American Standards Association (ASA) system, Orthogonal Rake System (ORS) or ISO old system, Normal Rake System (NRS) or ISO new system, and Maximum Rake System (MRS). Various systems use various names of the cutting edge angles.

What is principal cutting edge angle?

Principal Cutting Edge Angle, abbreviated as the PCEA, is the angle between cutting plane (πC) (which contains principal cutting edge) and the longitudinal feed direction, measured on reference plane (πR). It is usually designated by Φ. Both the ORS system and NRS system of tool designation use this Principal Cutting Edge Angle for designation of a turning tool.

Value of principal cutting edge angle

Value of the Principal Cutting Edge Angle (PCEA) of an SPTT varies depending on the need and purpose of machining. Usually it ranges from +45º to +90º. Thread cutting tools usually have PCEA = 55º or 60º. Higher value of PCEA reduces strength of tool tip; whereas, lower value of PCEA may hamper chip removal (shearing) action.

Effects of PCEA

- By increasing the principal cutting edge angle (say from 45º to 90º), the traverse component of cutting force can be reduced.

- However, increase in principal cutting edge angle will result in increase in cutting temperature.

References

- Book: Principles of Mechanical Engineering by S. Singh (S. Shand).

- Book: Machining and Machine Tools by A. B. Chattopadhyay (Wiley).

- Book: Metal Cutting: Theory And Practice by A. Bhattacharya (New Central Book Agency).

- Book: Manufacturing Processes by J. P. Kaushish (PHI).

- Book: Manufacturing Science by M. I. Haque and S. Khan (PHI).