In abrasive jet machining, high velocity (100 – 300m/s) jet of abrasive grits accelerated by pressurized gas is allowed to strike the work surface for material removal by erosion. Kinetic energy of the abrasives is utilized to create micro-indentation on work surface. A nozzle is employed to direct the abrasive jet towards work surface at a particular impingement angle from a fixed stand-off distance. It is assumed that only abrasive particles partake in erosion action (carrier gas does not participate in erosion). In order to control erosion rate, it is essential to know material removal rate of the process. MRR can be modeled on the basis of following assumptions. For detail modeling, you may follow the below link.

- Read more: Estimation of MRR in AJM (Modeling).

List of assumptions for modeling MRR in AJM

- Only abrasive particles participate in erosive action. Carrier gas has no role in erosion. Read: Functions of carrier gas.

- Abrasive grits are infinitely rigid thus do not undergo any deformation during impact. So none of the abrasive grits break or lose its sharp edges during impact.

- Grits are perfectly spherical and each abrasive particle has equal average diameter. (Practically abrasives should have sharp edges and must be of irregular shape to enhance material removal rate).

- Every particle equally participates in material removal action (each particle creates same indentation and all particles participate in erosion).

- Abrasive jet strikes the work surface vertically, so impingement angle (θ) is 90º.

- There is no jet spreading when it moves through stand-off distance (SOD).

- There is no collision of fresh abrasive jet with the used abrasive grits. So no loss of kinetic energy of jet.

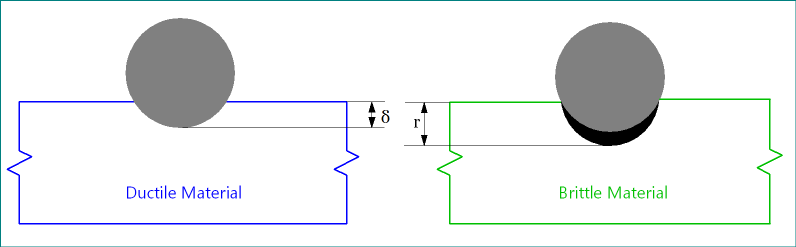

- For ductile materials, volume of material removed by single impact is equal to the volume of single indentation; whereas, for brittle materials, volume of material removed by single impact is equal to the volume of hemispherical crater having diameter equals to chord length of the indentation (see figure below).

Reference

- Book: Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. Ltd.).

- Book: Advanced Machining Processes by V. K. Jain (Allied Publishers Private Limited).

- Book: Nonconventional Machining by P. K. Mishra (Narosa Publishing House).