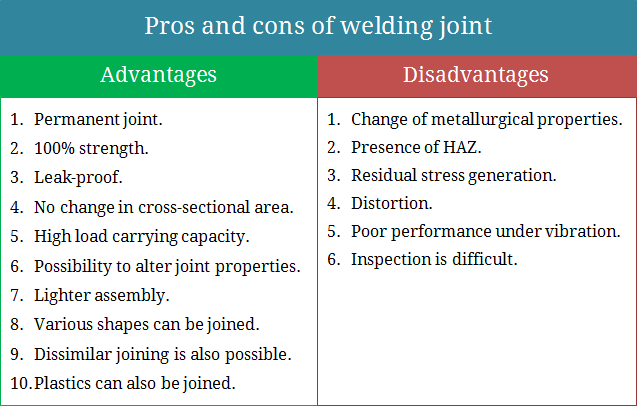

Welding is one type of permanent joining process by which two or more solid components can be joined to form a unit. There exist many other joining processes including few permanent joining processes and many temporary joining processes. Other than welding, rivet joint and adhesive joint are also permanent joining processes. Among temporary joining processes, fasteners, cotter joint, knuckle joints, etc. are commonly used. Despite presence of many alternative processes, welding offers many advantages over others. Pros and cons of welded joint are discussed in the following sections.

- Read more: Definition of welding.

- Read more: Classification of welding processes.

Advantages of welding joint

Welded joint is a permanent joint—Basically permanent joints don’t allow dismantling of jointed parts without rupturing them. So jointed components can be hold tightly without failure or leakage.

Superior strength of joint—Strength of sound welded joint is similar to that of parent components; sometime even more than that. As a thumb rule, strength of the welded joint is considered as 100%.

Leak-proof joining—Welded joint offers totally leak-proof joining, if welding is carried out properly.

No need to drill hole on parent parts—In case of riveted joint (another permanent joining process) holes are required to drill on the parent components and this considerably reduces strength of parent components. Welded joint does not require such holed to be drilled on parent parts, except for edge preparations (which are permanently filled by filler metal, so no reduction in actual strength).

High load carrying capacity—Since strength of welded joint is similar to that of parent parts, load carrying capacity of welded components remains unaltered before and after joining.

Possibility to alter mechanical properties—By utilizing appropriate filler material, shielding gas and electrode coating, various mechanical properties of the weld bead can be improved to desired level.

Welded assemblies are lighter—Compared to riveted joint (which needs additional straps, rivets, etc.), welded joints are light in weight. Read: Difference between welded joint and riveted joint.

Various shapes can be joined—Possibility of joining various shapes including plates, rods, sheets, etc. makes welding process unique among various joining processes.

Dissimilar metal joining—Joining of two or more dissimilar metals are also possible, with or without the application of filler. However, dissimilar metal joining needs extra precautions.

Possibility of joining plastics—Other than metals, plastics can also be welded in various ways.

Disadvantages of welding joint

Change in metallurgical properties—Since base plates are heated to an elevated temperature and then cooled down to room temperature during welding, metallurgical changes take place surrounding the weld bead (heat affected zone—HAZ). Mostly such changes are undesirable.

Residual stress generation—Because of uneven heating and cooling, residual stress generates within the welded structures. Such residual stress is usually undesirable as it sharply reduces load carrying capacity of welded structures.

Distortion of the components—Uneven heating and cooling is also associated with distortion of jointed structures, which causes dimensional inaccuracy and thus rejected parts.

Poor vibration sustaining capability—Welded joints are prone to vibration and thus fail if used for longer duration under vibration. In such scenario riveted joints are preferable.

Inspection is difficult—Checking presence of defects within welded joints is a bit difficult task and need sophisticated testing methods (non-destructive testing) for inspection, which are usually costlier.