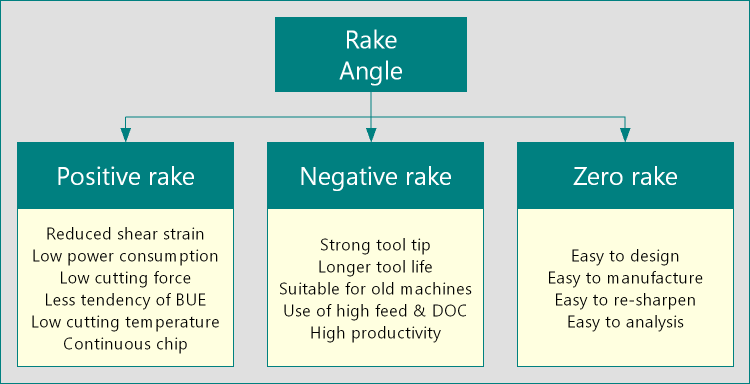

Rake angle of a cutting tool is defined as the angle of orientation of tool’s rake surface from the reference plane (and measured on some other plane). Rake surface is basically chip flowing surface; whereas, reference plane (πR) is a plane perpendicular to cutting velocity vector (Vc) in machining. Based on the orientation of rake surface with respect to reference plane, rake angles (γ) can be divided into three groups—positive rake angle, negative rake angle and zero rake angle. Each has certain pros and cons relative to other. For better understanding of this classification, you may read: Concept of positive rake, negative rake and zero rake.

What is negative rake angle?

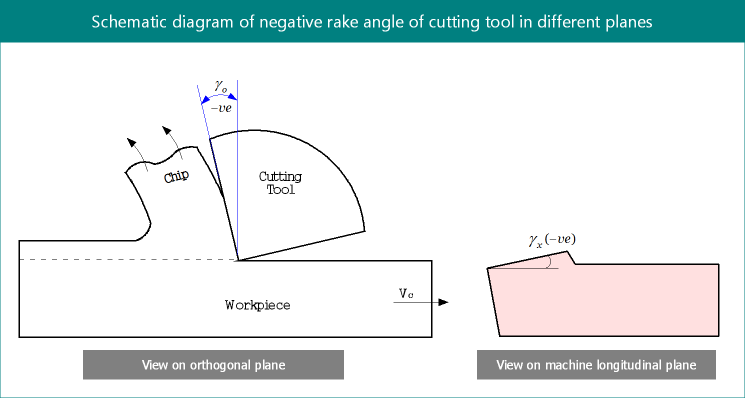

A negative rake occurs when sum of the clearance angle and wedge angle of cutting tool is more than 90º (angles measured on orthogonal plane). As schematically shown here, a positive rake makes the tool tip comparatively thicker by increasing wedge angle. Due to higher wedge angle, strength of tool tip increases and consequently tool becomes more sustainable under severe cutting temperature and impact loading. Thus tool life increases. The following passages elaborate the advantages and disadvantages of negative rage angle on a cutting tool.

Advantages of negative rake angle

Stronger tool tip—Larger wedge angle makes the tool tip strong enough to sustain under higher feed and depth of cut. Thus material removal rate (MRR) can be enhanced using such tool without sacrificing tool life.

Longer tool life—It takes higher time to worn out a negative rake tool and thus life of cutting tool enhances. Less chance of catastrophic failure also contributes in improving tool life.

Suitable for old machine tools—Usually old machine tools create vibration because of various worn out parts and loose joints. For such machines, cutting tool with negative rake is preferred as it can absorb impact loading as well as can sustain longer under small vibration.

Larger feed and depth of cut—In order to increase material removal rate (MRR) for enhancing productivity, higher value of feed rate and depth of cut can be utilized while machining with a negative rake tool. However, it will increase cutting force and may severely hamper the product quality.

Disadvantages of negative rake angle

High shear deformation—Deformation of chip material during shearing action is very high and this has many detrimental effects both on tool and workpiece.

High normal force on tool—Negative rake makes the normal force larger as compared to frictional force (attributed to Merchant Circle Diagram). It can cause tool deflection and vibration, which are undesirable during machining.

More power consumption—Higher the shear deformation larger will be the chip thickness and thus Chip Reduction Coefficient (CRC) will also increase. Higher CRC indicates more cutting force and thus higher cutting energy or power consumption. Thus lower depth of cut and feed rate has to be utilized for a given rated power of the machine tool.

Built up edge retention—Lower frictional force (from Merchant Circle Diagram) may not exceed bonding force of the built up edge and thus it will retain on the tool tip for a longer time (until frictional force exceeds bonding force).

- Advantages and disadvantages of positive rake angle in cutting tool

- Difference between positive rake and negative rake angle

References

- Book: Principles of Mechanical Engineering by S. Singh (S. Shand).

- Book: Machining and Machine Tools by A. B. Chattopadhyay (Wiley).

- Book: Metal Cutting: Theory And Practice by A. Bhattacharya (New Central Book Agency).

- Book: Manufacturing Processes by J. P. Kaushish (PHI).

- Book: Manufacturing Science by M. I. Haque and S. Khan (PHI).