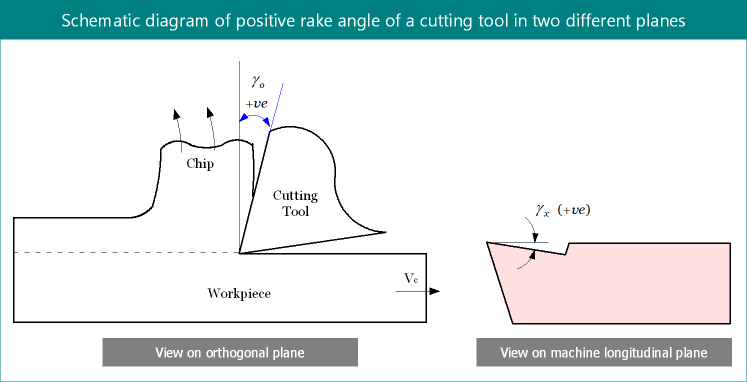

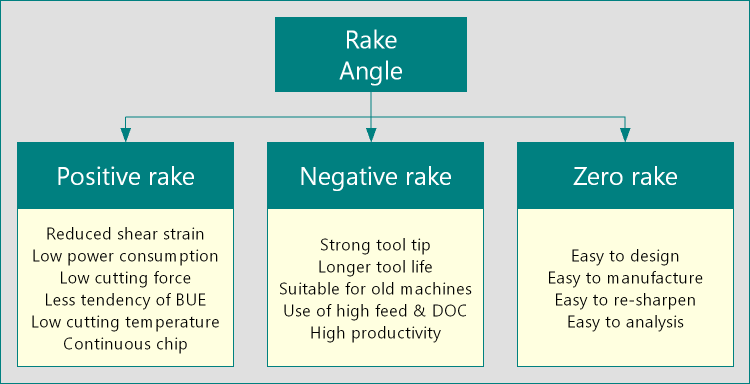

Rake angle of a cutting tool is defined as the angle of orientation of tool’s rake surface from the reference plane (and measured on some other plane). Rake surface is basically chip flowing surface; whereas, reference plane (πR) is a plane perpendicular to cutting velocity vector (Vc) in machining. Based on the orientation of rake surface with respect to reference plane, rake angles (γ) can be divided into three groups—positive rake angle, negative rake angle and zero rake angle. Each has certain pros and cons relative to other. For better understanding of this classification, you may read: Concept of positive rake, negative rake and zero rake.

What is positive rake angle?

A positive rake occurs when sum of the clearance angle and wedge angle of cutting tool is less than 90º (angles measured on orthogonal plane). As schematically shown here, a positive rake makes the tool tip comparatively sharper by reducing wedge angle, and thus shearing action occurs smoothly during machining. However, due to lower wedge angle, strength of tool tip reduces and consequently tool becomes vulnerable under severe cutting temperature and impact loading. The following passages elaborate various advantages and disadvantages of positive rake angle on a cutting tool.

Advantages of positive rake angle

Reduced shear strain—Higher the value of positive rake angle lower will be the shear strain. Lower shear strain in machining indicates less energy requirement for shearing.

Low power consumption—Due to lower wedge angle and reduced shear strain, cutting or shearing occurs easily with minimum effort. This reduces power (or energy) consumption while machining a particular work material under specific cutting condition. Thus higher feed rate or depth of cut can be utilized without much problem (within the rated power of machine tool) to enhance material removal rate (MRR) and productivity.

Low cutting force—Due to less shear deformation of chip, Chip Reduction Coefficient (CRC) also reduces. This results in lower cutting force, which consequently eliminates detrimental effects of high force (such as vibration, inaccuracy, chatter marks, etc.).

Lower tendency of built-up edge formation—Built-up edge, forms on the rake surface of the cutting tool, breaks down quickly and flow away with chip if tool with positive rake angle is used.

Lower cutting temperature—Although heat generation in machining depends greatly on other factors, positive rake angle contributes in reducing heat generation during machining. This protects both the tool and job from detrimental effects of the severe cutting temperature.

Favorable for continuous chip formation—Since shear deformation is low, so positive rake angle offers favorable condition for continuous chip formation, which indicates better machinability.

Disadvantages of positive rake angle

Weak tool tip—As positive rake angle indicates lower wedge angle, so strength of tool tip reduces. Thus capability of the cutting tool to withstand higher cutting force and absorbing larger heat during machining are also reduces. Thus higher speed, feed and depth of cut may not be applied.

Lower tool life—Tools with positive rake angle reaches their life time quickly due to gradual wear, especially flank wear.

Not suitable for old machines—Old machine tools usually induce vibration during cutting due to various worn out parts and loose joints. In such case use of cutting tools with positive rake angle should be avoided.

- Advantages and disadvantages of negative rake angle in cutting tool

- Difference between positive rake and negative rake angle

References

- Book: Principles of Mechanical Engineering by S. Singh (S. Shand).

- Book: Machining and Machine Tools by A. B. Chattopadhyay (Wiley).

- Book: Metal Cutting: Theory And Practice by A. Bhattacharya (New Central Book Agency).

- Book: Manufacturing Processes by J. P. Kaushish (PHI).

- Book: Manufacturing Science by M. I. Haque and S. Khan (PHI).