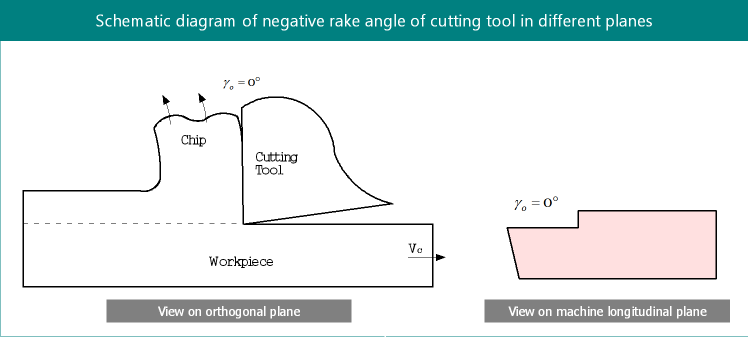

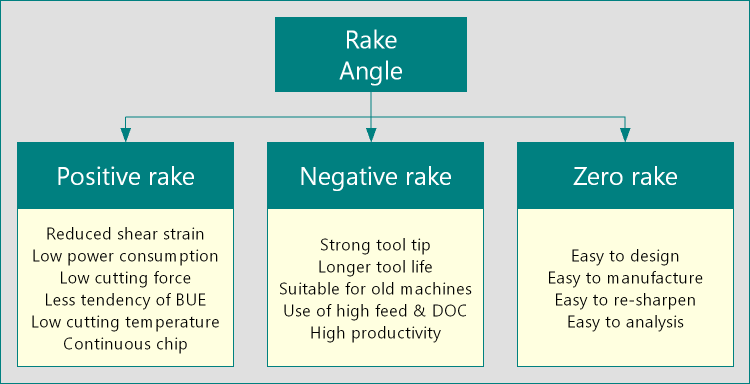

Rake angle of a cutting tool is defined as the angle of orientation of tool’s rake surface from the reference plane (and measured on some other plane). Rake surface is basically chip flowing surface; whereas, reference plane (πR) is a plane perpendicular to cutting velocity vector (Vc) in machining. Based on the orientation of rake surface with respect to reference plane, rake angles (γ) can be divided into three groups—positive rake angle, negative rake angle and zero rake angle. Each has certain pros and cons relative to other. For better understanding of this classification, you may read: Concept of positive rake, negative rake and zero rake.

In case of a zero rake angle (or neutral rake angle), the rake surface of the tool merges with the reference plane and the rake surface becomes a flat surface. A positive rake makes the tool tip less strong by reducing wedge angle; while, a negative rake overcomes this lacuna but increases the cutting power consumption because of higher shear deformation. A zero rake angle in intermediate of positive rake and negative rake and thus eliminates the disadvantages of both of them to some extent.

Advantages of zero rake or neutral rake angle

Easy to design and manufacture—This is the most important advantage of utilizing a tool with zero rake angle. Due to easy design and fabrication, tool cost is also considerably lower as compared to positive or negative rake.

Easy to re-sharpen worn out tool—Worn out tools can be re-sharpened by grinding. For this purpose the tool is needed to clamp on a vice with various adjustments based on tool angles. This is a complicated and time consuming task. Tool with zero rake angle makes it easier and faster for setting on the vice while re-sharpening it.

Easy calculations for estimating machining force—Cutting force can be estimated using Merchant Circle Diagram. This estimated value give an idea about the rage of cutting parameters that can be utilized to improve productivity. Such calculations are easier when tool has a zero rake angle.

Other advantages of zero rake angle

- It increases tool tip strength and also tool life as compared to positive rake tool

- It reduces cutting force and consequently cutting power consumption as compared to negative rake tool

- It improves machinability by reducing chip thickness, cutting force, cutting temperature, etc. as compared to negative rake tool.

References

- Book: Principles of Mechanical Engineering by S. Singh (S. Shand).

- Book: Machining and Machine Tools by A. B. Chattopadhyay (Wiley).

- Book: Metal Cutting: Theory And Practice by A. Bhattacharya (New Central Book Agency).

- Book: Manufacturing Processes by J. P. Kaushish (PHI).