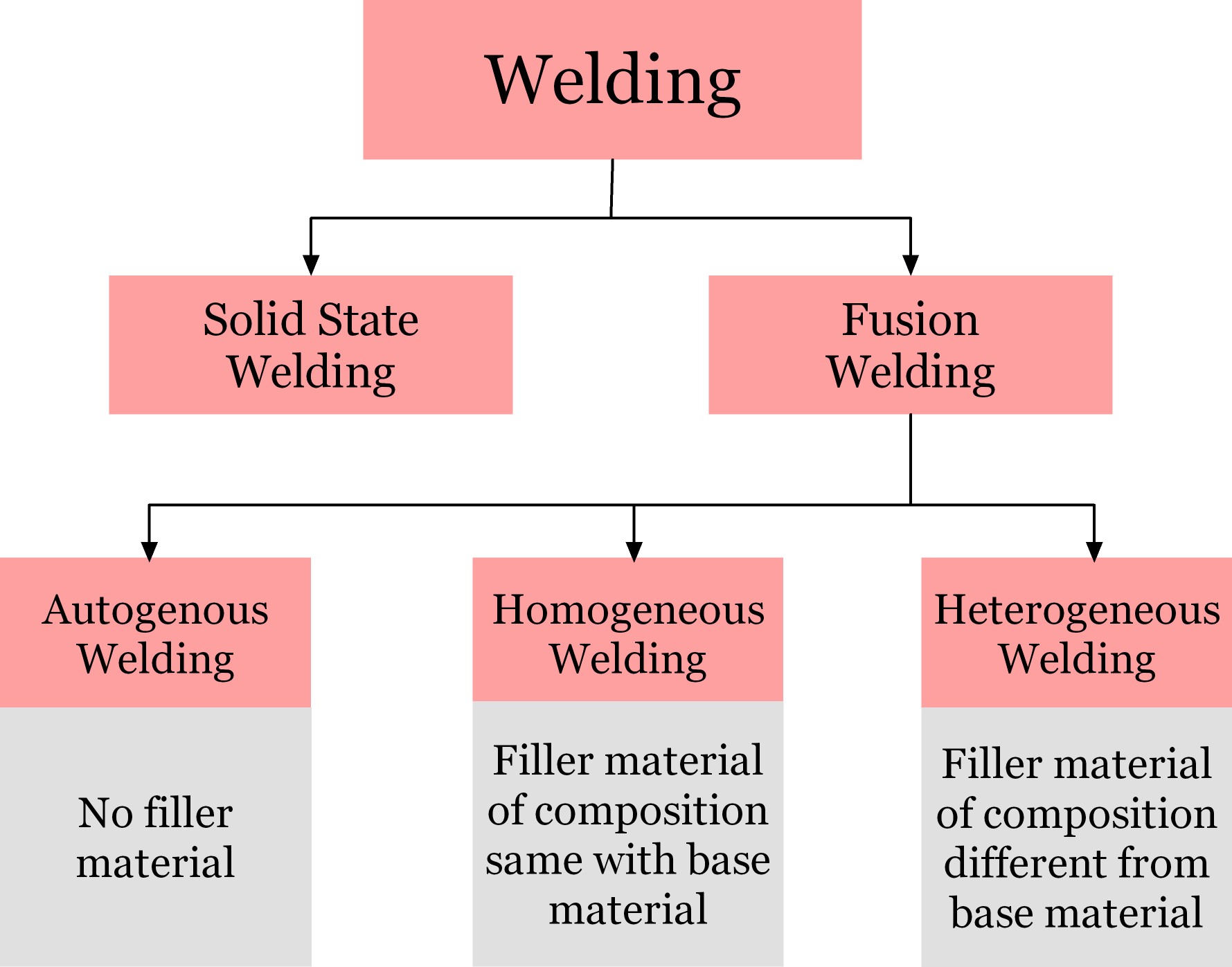

Welding processes can be broadly classified into two groups—Fusion welding and Solid-state welding. Fusion welding comprises all those welding processes where heat is directly applied from an external source in order to fuse or melt faying surfaces of base metals to form weld bead. This heat can be applied in various means, such as by electric arc, burning oxy-fuel gas, laser beam, etc. On the other hand, solid-state welding processes need external pressure to make joining. In such processes heat may inherently produce internally, but direct application of heat is not required for joining.

- Read more: Classification of welding processes.

Classification of fusion welding processes—Autogenous, Homogeneous & Heterogeneous

While joining by fusion welding processes, filler material can be applied during welding, if required. Due to application of external heat, this filler material melts down and deposits on weld bead to supply excess material required for filling the root gap for obtaining a sound weld. It is to be noted that application of filler material is not necessary; it is usually applied when sufficient root gap exists or edge preparation is conducted. According to the application and nature of filler material, fusion welding processes can be grouped into three categories—Autogenous welding, Homogeneous welding and Heterogeneous welding.

What is heterogeneous welding? – Examples

Heterogeneous welding is one way of performing fusion welding with the application of external filler whose metallurgical composition is substantially different from that of the base metals. So if filler material is applied during joining and the metallurgical composition of filler is different from that of the base metal then it is termed as heterogeneous welding. It is to be noted that heterogeneous welding is not a particular type of welding process like MMAW, TIG, GMAW, etc.; instead, it is one of the three different modes or ways of doing fusion welding.

Brazing and soldering are common examples of heterogeneous joining. Manual Metal Arc Welding (MMAW), Gas Metal Arc Welding (GMAW), Flux Cored Arc Welding (FCAW), etc. can also be performed in heterogeneous mode.

- Autogenous welding – example, advantage & disadvantage.

- Homogeneous welding – example, advantage & disadvantage.

- Difference between homogeneous and heterogeneous welding.

Advantages of heterogeneous welding

- Various weld properties, such as stress and corrosion resistance, etc. can be enhanced by choosing appropriate filler material.

- Thick plates can be welded efficiently with proper edge preparation.

- Strength of the joint is excellent—better than autogenous welding.

- Due to sufficient supply of molten metal, tendency of crack formation during solidification reduces.

- Welding of various joints, like butt joint, lap joint, tee joint, corner joint, etc. are also possible.

- Joints are more reliable, so less chance of failure if welded properly.

Disadvantages of heterogeneous welding

- Because of the non-uniformity in composition among the filler and base metals, there exist high tendency of development of weld discontinuity and crack formation.

- Compatibility between filler material and base material must be checked properly otherwise defective welding will be produced.

- Filler material is usually costlier and it also requires proper maintenance.

- Application of excess filer material causes high reinforcement on weld bead, which are required to remove after welding by grinding.

- Appearance of weld bead is not good.

- Sputter may also produce if process parameters are not chosen optimally.