In general, kerf width is the actual width of the slot cut either by a cutter or by some kinds of high energy jet or beam. The cutter may be a drill, end-milling cutter or even saw. High energy jet or beam could be an abrasive jet or water jet or electron beam or laser beam or similar things. Whatever be the case, the actual width of cut may not be exactly same with the cutter or jet or beam diameter. This actual width of slot is termed as kerf width. If process parameters are not chosen optimally, the kerf width becomes substantially larger than cutter or jet or beam diameter, which may lead to inaccurate machining and thus rejected parts.

Why kerf width is larger than jet diameter in AJM?

In AJM, high velocity jet of abrasives, accelerated by means of pressurized gas, strikes the work surface and erodes material in the form of tiny metal particles. A nozzle is used to direct the abrasive jet onto the work surface at the required position. The tip of the nozzle is kept at some distance (1 – 10mm) away from the concerned work surface. This distance is termed as Nozzle Tip Distance (NTD) or Stand-Off Distance (SOD). Now there exist two reasons behind increased kerf width in abrasive jet machining (AJM) process, as provided below.

- Spreading of abrasive jet while travelling through the SOD.

- Side cutting caused by abrasive grits while coming out of cutting zone.

Effect of SOD on kerf width in AJM

After coming out from the nozzle, the abrasive jet tends to diverge as it experiences much lower surrounding pressure and as a result its diameter continuously increases. So higher the SOD, larger will be the jet diameter. However, suitable SOD is indispensably necessary to provide sufficient passage for abrasive grits to come out from the machining zone. Therefore, the resultant jet diameter that impinges the work surface is little larger than nozzle diameter and consequently a larger kerf width is obtained.

Side cutting caused by coming out grits

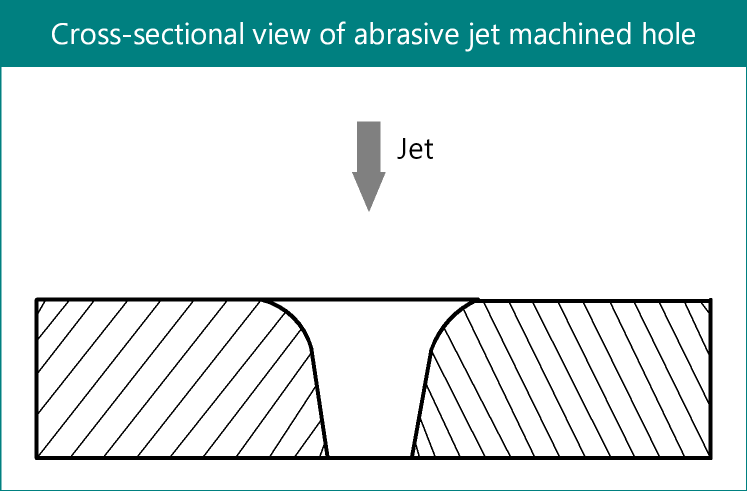

The grits coming out of the cavity after initial impact also erode material from side walls. This is also termed as side cutting. It substantially contributes in increasing the kerf width. However, if the cut depth is small, then this mismatch may not be palpable.

References

- Book: Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. Ltd.).

- Book: Nonconventional Machining by P. K. Mishra (Narosa Publishing House).