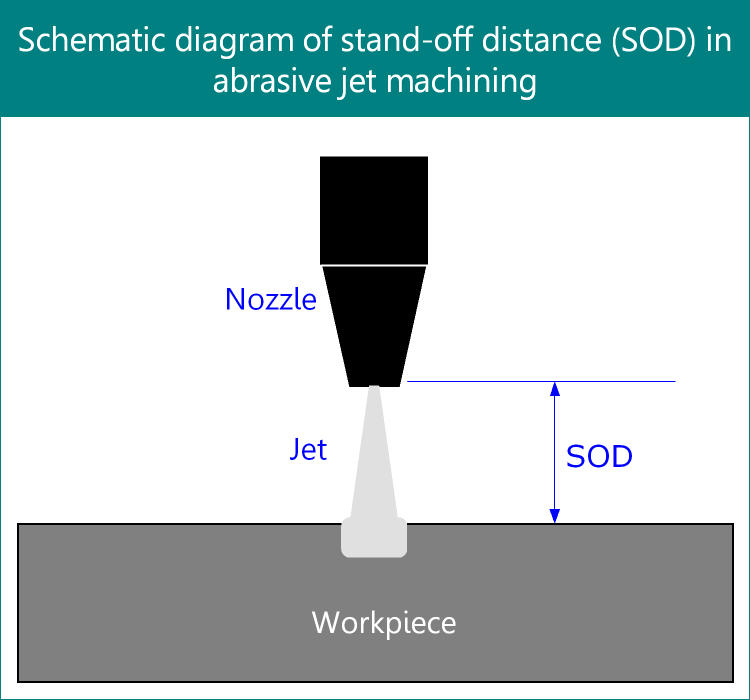

In abrasive jet machining (AJM), a nozzle directs high velocity jet of abrasives towards work surface in order to gradually remove material by impact erosion. As schematically depicted below, the gap between the nozzle tip and the work surface is called Stand-Off Distance (SOD) or Nozzle Tip Distance (NTD). This stand-off distance is one crucial factor in abrasive jet machining as it influences material removal rate (MRR) as well as accuracy of machined profile. How this SOD affects accuracy in abrasive jet machining process is elaborated in the following passages.

Effects of stand-off distance (SOD) on machining accuracy

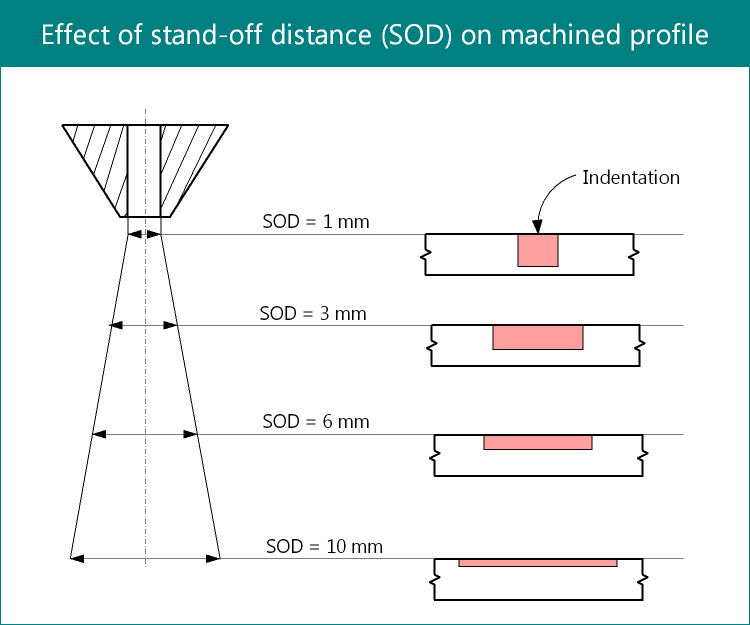

Once the abrasive jet leaves the nozzle, it experiences much lower surrounding pressure as compared to stagnation pressure within the jet itself. Thus the jet starts diverging as it pass through the stand-off distance. Consequently, diameter of jet enhances whereas velocity decreases (flow rate is constant, so jet cross-sectional area is inversely proportional to jet velocity). Therefore, a larger stand-off distance results in wider jet having low kinetic energy (velocity). Since only kinetic energy of abrasive grits are utilized for material removal by erosion, so longer SOD will degrade erosion capability of the jet. Thus result will be very low penetration but a wider machined area. It is worth noting that if SOD becomes substantially larger then no palpable material removal action may occur at all.

On the other hand, smaller stand-off distance will result in deeper but narrow penetration. Thus such SOD is preferable for cutting or drilling. However, too small SOD may not provide sufficient passage for the used abrasive grits to come out of the machining zone after striking. Presence of used abrasives in the machining zone is highly undesirable as such grits tend to reduce the velocity (kinetic energy) of fresh jet due to collision. Thus an optimum stand-off distance is to be maintained based on requirement, material properties as well as other process parameters. Following diagram shows how, with increase in SOD, profile of the machined slot changes in abrasive jet machining (AJM).

Reference

- Paper: N. Ramachandran and N. Ramakrishnan (1993); A review of abrasive jet machining; Journal of Materials Processing Technology; Vol. 39; pp. 21-31.

- Book: Nonconventional Machining by P. K. Mishra (Narosa Publishing House).

- Book: Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. Ltd.).