What is Stand-Off Distance (SOD)?

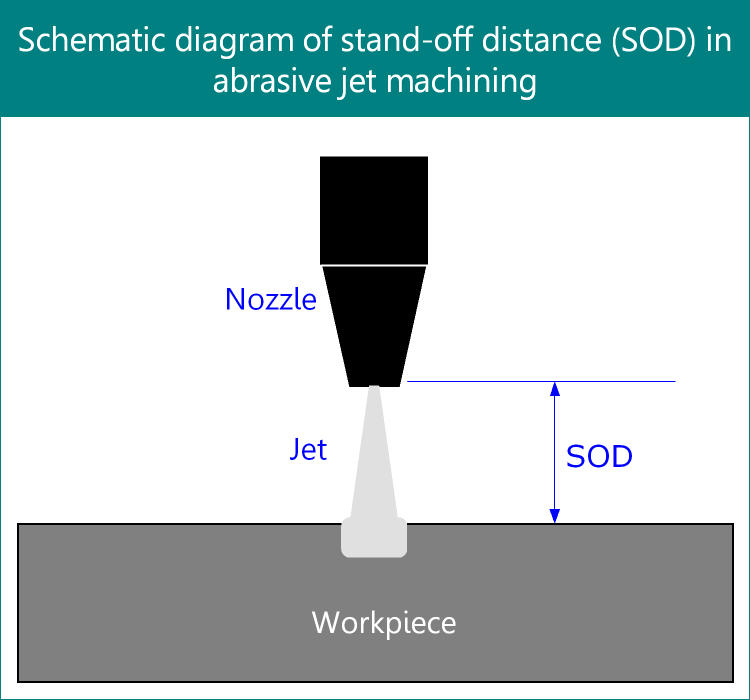

Distance from work surface to tip of the nozzle in abrasive jet machining set-up is called Stand-Off Distance, abbreviated as SOD. It is also called Nozzle Tip Distance (NTD). The below figure schematically depicts the stand-off distance in AJM. It is one crucial factor that determines abrasive jet machining performance including material removal rate, achievable depth of penetration, accuracy of the machined feature, and also the area of cut.

The value of SOD commonly varies from 1 – 10mm.

Effects of stand-off distance (SOD) on machined profile

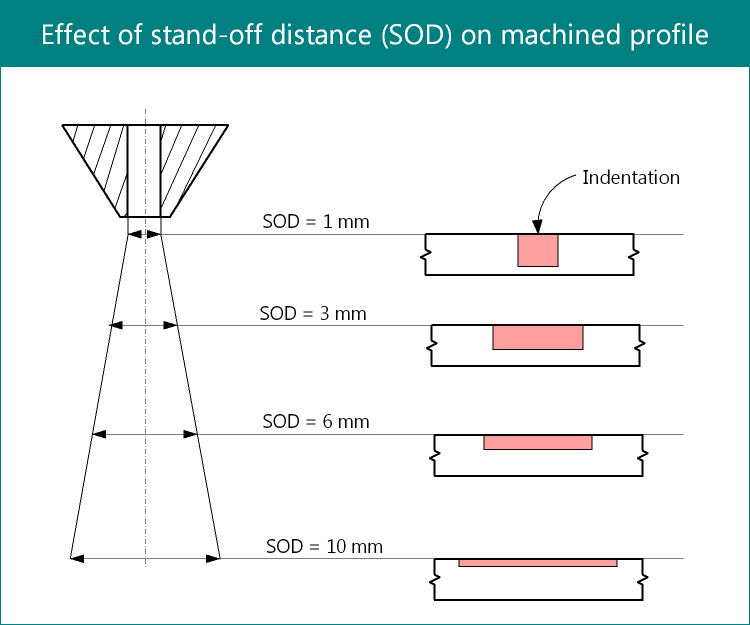

High velocity abrasive jet, after discharging from the nozzle, remains intact for a small distance and then starts spreading as the surrounding pressure is substantially lower than the stagnation pressure of the jet. Thus the diameter of abrasive jet expands gradually with increase in distance from nozzle tip and consequently velocity (or kinetic energy) of the jet reduces. Therefore, smaller SOD provides a narrow and high velocity jet; whereas, larger SOD provides a wider and low velocity jet. Consequently, smaller SOD can cut a deeper but narrow slot or hole; while larger SOD can cut a shallow but wider area (suitable for cleaning of oxides, removing coating, etc.). The same is depicted in the figure below.

Effects of stand-off distance (SOD) on material removal rate

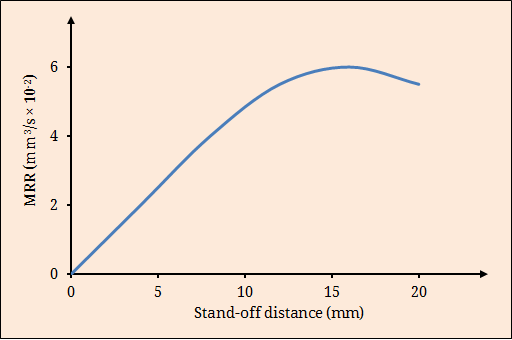

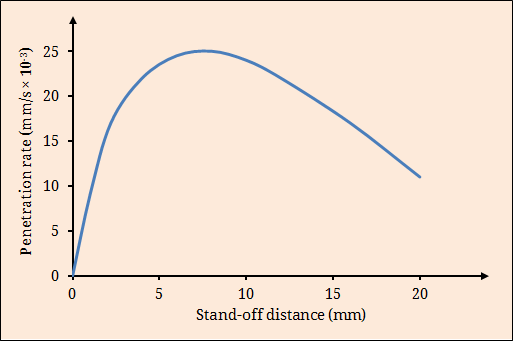

Diameter of the abrasive jet gradually expands due to spreading as the distance from nozzle tip increases and consequently velocity (or kinetic energy) of the abrasive particles reduces. Since kinetic energy imparted by the grits is used to gradually erode material from work surface, larger SOD results in lower penetration as well as lower material removal rate (MRR).

On the other hand, if SOD is too small then sufficient passage will not be available for the used abrasive grits to come out from the machining zone after impact. It can substantially descend velocity of fresh jet because of collision that can lead to reduced effectiveness of the jet in terms of material erosion. Therefore, initially with increase in stand-off distance, both the MRR and penetration increase gradually; however, after certain limit, both decrease with further increase in SOD, as depicted below. Thus an optimum value of stand-off distance is required for obtaining satisfactory performance in abrasive jet machining.

Reference

- Book: Nonconventional Machining by P. K. Mishra (Narosa Publishing House).

- Book: Nontraditional Manufacturing Processes by G. F. Benedict (Manufacturing Engineering and Materials Processing-19).

- Book: Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. Ltd.).