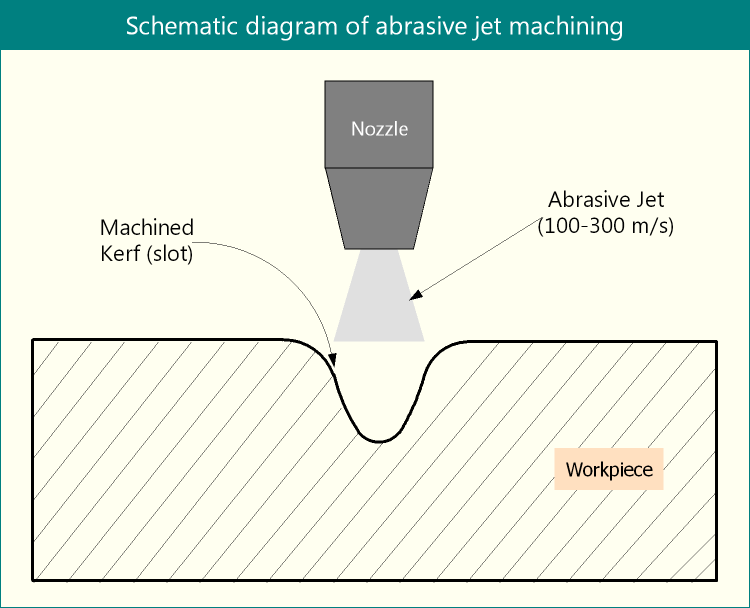

Abrasive Jet Machining (AJM) is one of the mechanical energy based modern machining processes where material is removed by controlled micro-cutting action caused by the impact of a concentrated high-velocity (100 – 300m/s) jet of abrasive grits accelerated by dehumidified pressurized gas (10 – 15bar). A nozzle directs the abrasive jet in a controlled way onto the work surface. When this high-velocity abrasive jet is made to impinge the work surface in a particular direction from a suitable stand-off distance (SOD), it erodes material primarily by micro-cutting and sometime assisted by brittle fracture.

Mechanism of material removal in abrasive jet machining is Impact Erosion.

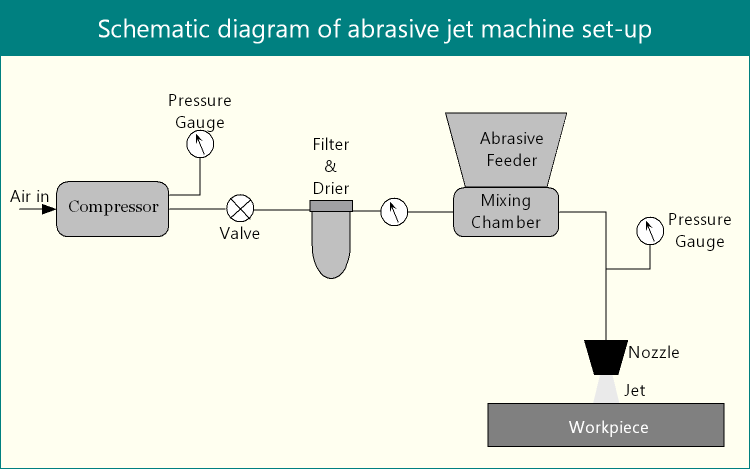

In Abrasive Jet Machining (AJM), usually air is directly taken from atmosphere, cleaned it and compressed it to a high pressure with the help of compressor. Loose abrasive particles having predefined average size are mixed with this pressurized gas in certain proportion (mixing ratio) and the mixture is then allowed to strike the work surface in the form of jet at a particular incident angle at very high velocity. A nozzle converts the hydraulic energy (pressure) of the jet-abrasive mixture into kinetic energy (velocity). After cutting action, grits leave the machining zone, which are then collected and disposed safely (usually, abrasive grits cannot be reused as grits lose sharpness after first impact).

AJM can efficiently cut hard and brittle materials, and thus can be used for drilling, cutting, deburring, deflashing, cleaning, and decoating. However, it is not suitable for soft and ductile materials, such as plastic, foam, etc., because the abrasive particles tend to get embedded on the work surface that hampers the cut quality. Although AJM process is noisy and less reliable, it can produce high surface finish even below 1µm, if controlled properly.

- Advantages and limitations of abrasive jet machining (AJM) process

- Applications of abrasive jet machining (AJM) process

References

- Book: Advanced Machining Processes by V. K. Jain (Allied Publishers Private Limited).

- Book: Nonconventional Machining by P. K. Mishra (Narosa Publishing House).

- Book: Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. Ltd.).