Calculate shear force and rate of heat generation at primary shear plane

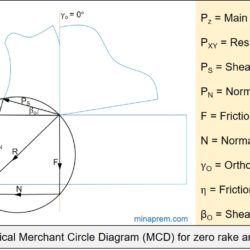

Question: In orthogonal turning of an engineering alloy, it has been observed that the friction force acting at the chip-tool interface is 402.5 N and the friction force is also perpendicular to the cutting velocity vector. The feed velocity is negligibly small with respect to the cutting velocity. The ratio of friction force to normal force associated with the chip‐tool interface is 1. The uncut chip thickness is 0.2 mm