Surface roughness determines the tribological characteristics (friction, wear and lubrication) of a machined surface. Although machining, the subtractive manufacturing process, is used mainly for obtaining smooth surface, different machining processes fetch various levels of surface finish. For example, conventional turning can give a finish in the order of 10 – 100µm; while precision turning can provide much better surface finish (in the order of 20 – 200nm). Apart from machining process, several cutting parameters significantly influence achievable surface finish.

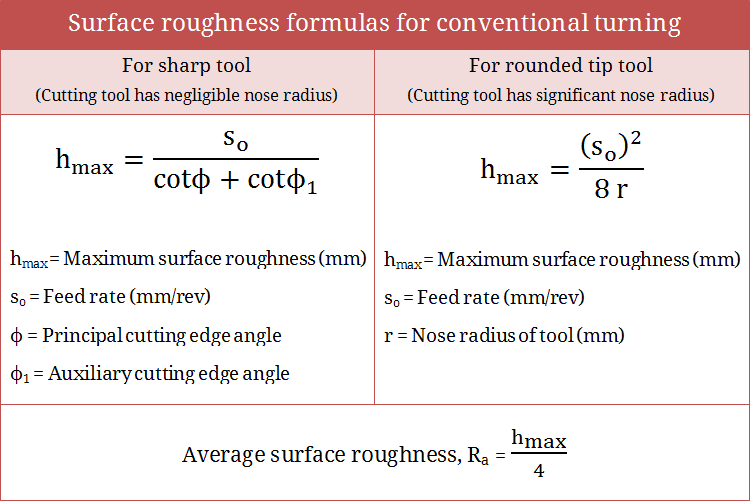

Among various machining parameters, nose radius of the cutting tool and feed rate are dominant factors. There are two mathematical formulas that are commonly applied for estimating surface roughness of a machined component. One of them is applicable for a sharp tool that has negligible nose radius as compared to depth of cut; while the other one is suitable when cutting tool has significant nose radius.

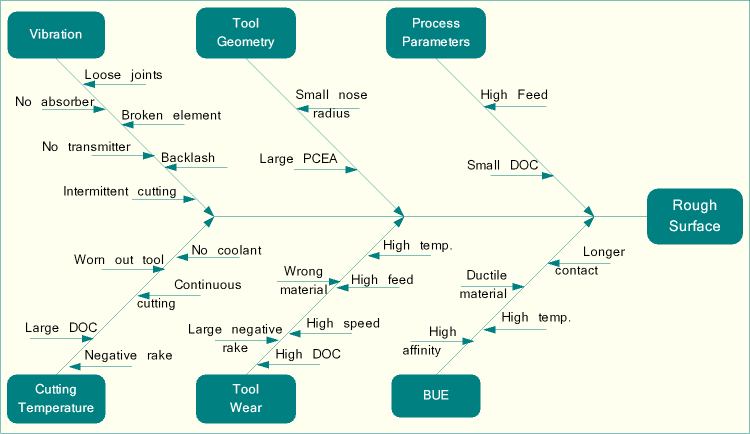

Various sources that influence surface roughness in machining

Feed rate—As evident from the above expressions, roughness parameter (hmax) is proportional to the feed rate. Thus if machining is carried out with higher feed rate then machined surface will also be rough. In order to improve finish, feed rate can be reduced; however, in that case material removal rate will degrade.

Nose radius—Surface roughness is inversely proportional to the nose radius of cutting tool (especially when depth of cut is comparable to nose radius). So from theoretical point of view, surface finish can be improved by increasing nose radius; however, this may lead to other undesirable problems such as higher cutting power requirement, unfavorable chip formation, etc. Again a specific tool has a specific nose radius, so it should be selected judiciously prior to operation.

Cutting edge angle—When nose radius of the tool is negligible, principal cutting edge angle and auxiliary cutting edge angle of the cutting tool contribute in surface roughness. They always tend to minimize roughness but their values are fixed for a specific cutting tool. Similar to nose radius, these angles are not process parameters and thus cannot be varied during operation.

Vibration in machine tool—Vibration may arise from different sources including inhomogeneity in work material, broken tool, broken elements in machine tool, stick-slip motion, etc. Such vibration can vary depth of cut, feed rate and also cutting force, which may lead to generation of poor surface.

Dry cutting environment—Excessive cutting temperature can also degrade surface quality. Dry environment accelerates rate of heat generation and thus use of cutting fluid can reduce possible effects.

Broken or worn out tool—A broken or worn out tool can severely damage machined surface by reducing amount of shearing and promoting ploughing, scratching and rubbing. It can also lead to high force fluctuation and uncontrollable vibration.

Apart from above common sources for surface roughness in conventional machining, there exist few other trivial sources also. Such factors include (i) quality of unmachined surface including surface roughness, cracks, voids, etc. (ii) homogeneity in work material, (iii) stick-slip motion of sliding parts in machine tool, (iv) eccentricity in workpiece or tool, (v) backlash in motion elements, (vi) tool tip modification, etc.

References

- Book: Advances in Manufacturing Technology XV by D. T. Pham, S. S. Dimov and T. O’Hagan (Professional Engineering Publishing Limited).

- Proceedings: K. S. Umashankar, B. J. Manujesh and N. A. Jnanesh; Recurrence Qualification Analysis – A Tool to Analyze the Surface Finish During Machining; Advances in Mechanical Engineering; 2010.

- Book: Machining and Machine Tools by A. B. Chattopadhyay (Wiley).

- Book: Metal Cutting: Theory And Practice by A. Bhattacharya (New Central Book Agency).