Determine shear angle, cutting force and thrust force for mild steel

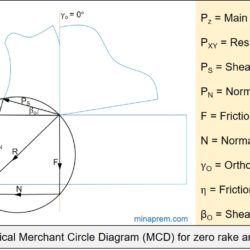

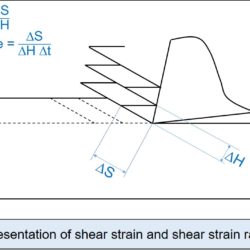

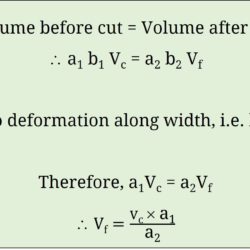

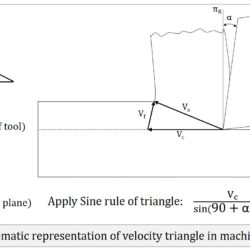

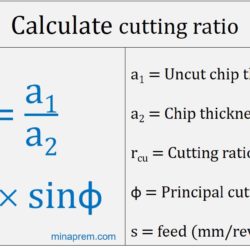

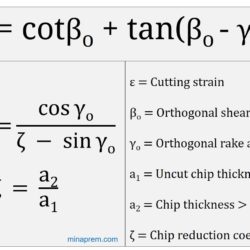

Question: Mild steel is being machined at a cutting speed of 200 m/min with a tool rake angle of 10°. The width of cut and uncut thickness are 2 mm and 0.2 mm, respectively. If the average value of co‐efficient of friction between the tool and the chip is 0.5 and the shear stress of the work material is 400 N/mm2, then determine: [ESE 2005] (i) The shear angle (ii)