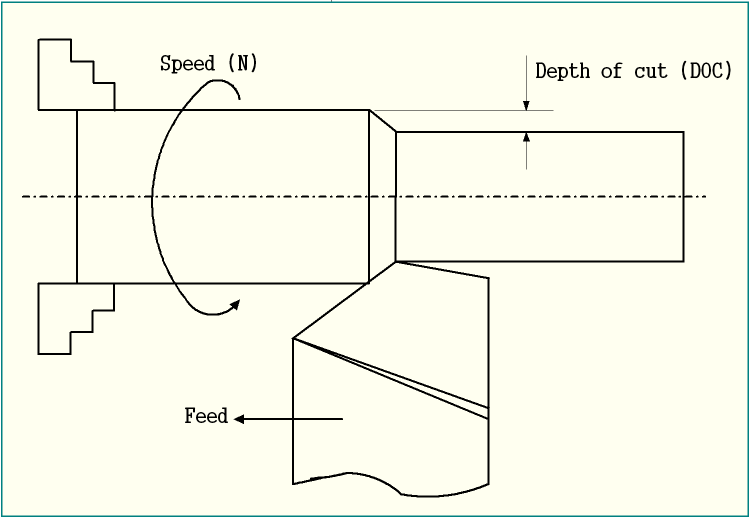

Basic intention of any conventional machining operation is to gradually remove excess layer of material (subtractive manufacturing) from a blank to impart a basic shape and size with reasonably smooth surface finish. For any machining or material removal operation, three relative motions between workpiece and cutting tool are indispensably necessary, which, in fact, are the primary cutting parameters. The simultaneous action of all three parameters causes material removal in the form of chip from the workpiece. These three cutting parameters or relative motions are provided below.

1. Cutting velocity (Vc)—The most important cutting parameter that provides necessary cutting motion. It can be imparted either on the cutting tool or on workpiece by either rotating it or reciprocating it. In case of either rotating tool (such as milling, drilling, grinding) or rotating workpiece (such as turning), the peripheral velocity of cutter or workpiece is considered as the cutting velocity. However, where neither the workpiece nor the tool rotates, the translation velocity of cutter or workpiece gives the intended cutting velocity. Learn more about cutting speed and cutting velocity.

2. Feed rate (s)—The auxiliary cutting motion is provided by the feed velocity. Usually the direction of feed velocity is perpendicular to that of the cutting velocity. The primary objective of feed velocity is to remove material from a large surface. Basically it helps in covering the entire surface of the workpiece by moving either cutting tool or workpiece. Learn more about feed rate.

3. Depth of cut (t)—The tertiary cutting motion that provides necessary depth of material that is required to remove by machining. It is expressed in mm. It is usually given in the third perpendicular direction (velocity, feed and depth of cut usually act in mutually perpendicular directions).

Effects of depth of cut (DOC)

Since depth of cut is one of the three main cutting parameters, so its value also affects overall machining performance and machining economy. Few common effects of DOC are enlisted below; for all effects in detail read: Effects of depth of cut on machining performance.

- Larger depth of cut indicates higher material removal rate (MRR), as MRR is proportional to the speed, feed and depth of cut. So productivity of machining can be enhanced by employing larger depth of cut and consequently machining cost can be reduced.

- Cutting force depends on chip load, which is proportional to depth of cut. Thus larger value of depth of cut can increase cutting force, which may hamper machining performance and induce vibration.

- Higher depth of cut may also break the cutting tool catastrophically, which is highly undesirable.

- It also influences chip thickness, type of chip produces, shear deformation, etc., which are indication of machinability.

Selection and value of depth of cut

Since depth of cut value is an important parameter that influences overall machining performance as well as economy, so an optimum value must be selected judiciously after considering a number of relevant factors. Usually, in conventional machining operations, depth of cut value varies between 0.1 – 1.0mm. Selection of its value requires attention on the following characteristics.

- Productivity requirement—Since material removal rate is expressed by the multiplication of cutting velocity, feed rate and depth of cut, so usage of larger depth of cut results in enhanced MRR. This, in turn, cuts down machining time and thus improves productivity.

- Quality of cut required—For finish cut, lower depth of cut should be provided; whereas, for rough cut, larger value can be utilized to shorten machining time.

- Machining operation—Various machining operations have the capability to handle various ranges of depth of cut. For example, milling operation using a side and face milling cutter can handle a larger depth of cut; while, its value is limited in knurling operation.

- Workpiece material strength—For machining hard and brittle materials, a lower value of depth of cut is recommended, otherwise the force may be very high and cutting tool may break.

- Capability of machine tool—Since depth of cut increases cutting force and vibration, so the capability of machine tool should also be considered.

References

- Book: Machining and Machine Tools by A. B. Chattopadhyay (Wiley).

- Book: Metal Cutting: Theory And Practice by A. Bhattacharya (New Central Book Agency).