Mechanism of material removal in abrasive jet machining (AJM) is impact erosion. Mechanical erosion is basically a combination of cutting wear and deformation wear. When high-velocity abrasive jet is made to impinge the work surface in a particular direction from a suitable stand-off distance (SOD), it erodes material primarily by micro-cutting and sometime assisted by brittle fracture.

What is impact force and how it differs from gradual loading?

External force can be applied on a solid body in two different ways—either gradually or suddenly. In case of gradual loading, load starts with zero and increases gradually at a finite rate and after a certain period of time it reaches to full load. Therefore, in gradual loading, entire load is applied over a finite period of time that may vary from, say, 10 seconds to 10 minutes. During this gradual loading, an average force (equals to half of the full load) is assumed to act on the body. Example of gradual loading is the load that is applied during tensile or compressive testing on UTM (Universal Testing Machine).

On the other hand, impact load is applied suddenly. That means the intensity of external force becomes zero to full load in literally zero duration. Thus rate of loading is theoretically infinite. However, in practical purpose, impact load is applied quickly, may be in a fraction of second. For example, impact force is applied during hammering, impact extrusion, etc.

In AJM, work material is subjected to impact loading

In case of abrasive jet machining (AJM), abrasive particles impinge the work surface at a very high velocity (100 – 300m/s). Say one such grit strikes the surface at 200m/s and penetrates by 0.5mm within the work surface before its velocity reaches to zero. So the deceleration is 8×107 mm/s2 and so will be the rate of increase in pressure/force (point loading). It will take roughly 5.0 milliseconds to reduce its velocity from 200m/s to 0. Thus it can be considered that impact force is applied on the work surface when abrasive particles strike on it.

Why AJM causes mechanical erosion?

Erosion is one type of wear that occurs by the impact of one solid surface against another solid surface. The wear rate depends on kinetic energy of particles (thus velocity), impingement angle and also size of particle. In abrasive jet machining, similar phenomenon occurs that means material is removed by erosive wear. In fact, impact erosion is the mechanism of material removal for all mechanical energy based advanced machining processes including AJM, AWJM, and USM.

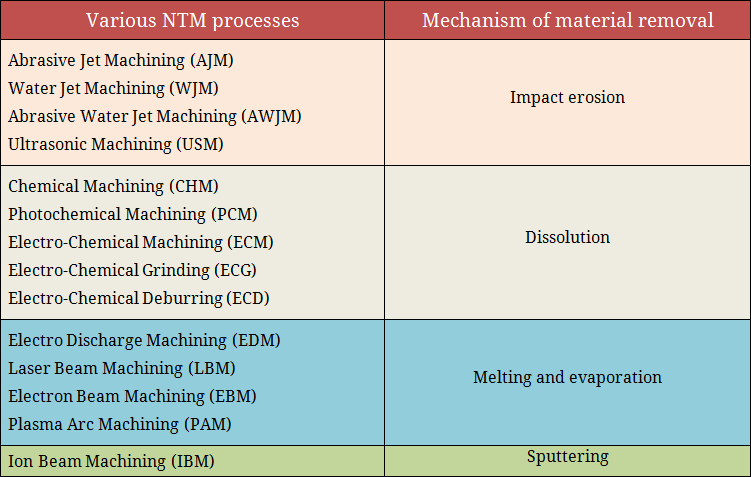

Mechanism of material removal in other NTM processes

Unlike conventional machining (where material is removed in the form of solid chips), in non-conventional machining processes material can be removed in different ways like solid grains, melting and vaporizing, ionic dissolution, atoms, etc. Following table illustrates basic mechanism of material removal in various non-traditional machining (NTM) processes.

References

- Book: Mechanical Wear Fundamentals and Testing, Revised and Expanded (Mechanical Engineering) by R. G. Bayer (CRC Press).

- Book: Nonconventional Machining by P. K. Mishra (Narosa Publishing House).