Question: During orthogonal machining of mild steel with a 10° orthogonal rake angle tool, the chip thickness ratio was found to be 0.4. Determine the shear angle. [GATE 2001]

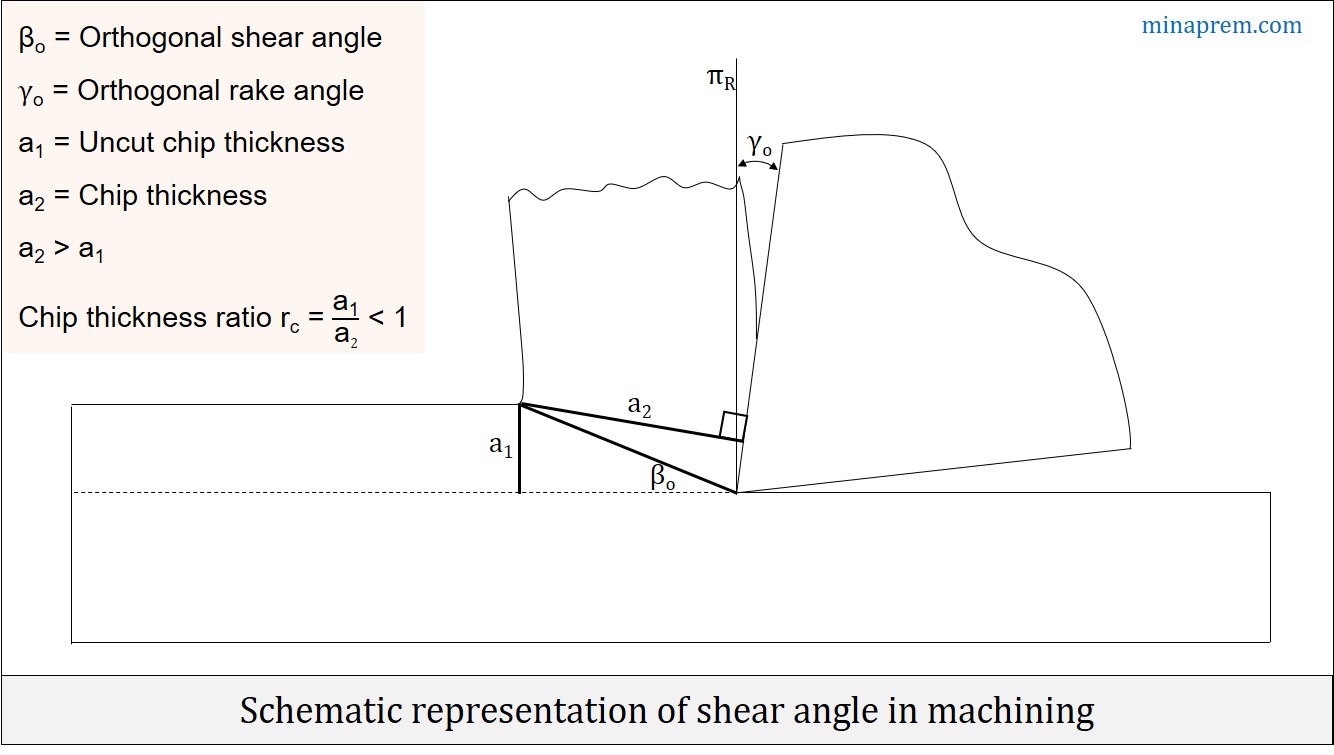

Solution: In conventional metal cutting processes, chip gets thickened after machining, and thus chip thickness (a2) becomes larger than uncut chip thickness (a1). The ratio between uncut chip thickness and chip thickness is termed as Chip Thickness Ratio (CTR). Its value is always less than 1. There exists another term called Chip Reduction Coefficient (CRC), which is the ratio between chip thickness and uncut chip thickness. Thus CRC is nothing but inverse of CTR. Orthogonal rake angle of the cutting tool is given as +10° and CTR is 0.4.

The shear angle is the angle of inclination of the shear plane from the cutting velocity vector (VC). It is denoted by βo as shown in figure. It is based on the assumption that shearing takes place in a concentrated 2-D plane instead of a region. For orthogonal machining, shear angle can be expressed in terms of Chip Reduction Coefficient (CRC, denoted by ζ) and orthogonal rake angle (γO) as given below.

\[\tan {\beta _O} = \frac{{\cos {\gamma _O}}}{{\zeta – \sin {\gamma _O}}}\]

In the given case

γO = +10°

CTR = 0.4

So, ζ = (1/0.4) = 2.5

\[\tan {\beta _O} = \frac{{\cos 10}}{{2.5 – \sin 10}} = 0.423\]

\[{\beta _O} = 22.93\]

Therefore, shear angle in the given case is 22.93°.